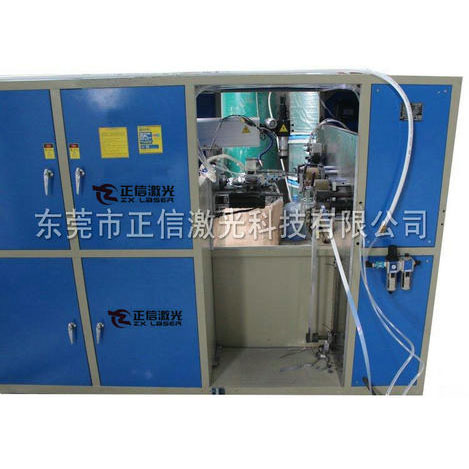

Hot keywords:Dongguan laser welding machine Automatic laser welding machine Laser welding machine manufacturers

|

Automatic laser welding machine |

Traditional stored energy welding machine |

|

Effect of welding |

|

|

The weld surface appearance, Burr-free, eliminating the grinding and polishing processes |

Weld is not formed, needs polishing and grinding process |

|

Welding efficiency |

|

|

Every 8 hours welding output at 7000 to 9000 , and high efficiency |

Skilled workers every day 8 hour production output of 3000 to 4500 or so, low production efficiency |

|

Welding defect rate |

|

|

Defect rate can be controlled within 0.1%Almost no defects |

Artificial defect rate of up to 1%-5% between the steel tape diameter wide defective rate higher and higher |

|

Cost of production |

|

|

Save labor: a worker can operate multiple devices to achieve fully automatic loading and unloading of welding, just ordinary workers fit. |

Skilled manual labor, and one can only look at a piece of equipment, costs are fully automatic laser welder twice times |

|

No polishing, |

Grinding and polishing, polishing costs each cost a few cents to a dime, |

|

Scrap costs extremely low, 10000 calculations (10000*0.1%=10 ) defective in the 10 or so, the negligible cost of waste. |

Higher scrap costs, 10000 calculations (10000*1%=100-10000*5%=500) defective in the 100 to 500 between value of steel as the material be |