|

|

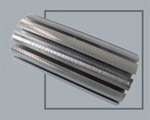

Vibration Motor Welding Worktable HWLLG01

◆PLC + man-machine interface control mode:

Dimensions: (L * W * H): 700 × 800 × 1400 (mm)

◆ Dimensions: (L * W * H): 700 × 800 × 1400 (mm)

◆ Profile frame, black PVC sealing board, safety light curtain protection, to meet international safety requirements;

◆ Using high-precision rotary table, with servo motor drive mode, the overall accuracy control within 0.02mm, the table with multiple stations, the efficiency will be increased to 12 / min;

|

|

|

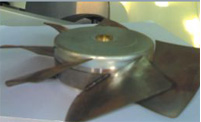

Fan motor blade welding table HWLAVC01

◆ Industrial PC control, dimensions (L * W * H): 900 × 1200 × 1700 (mm).

◆X-Y-Z three-dimensional automatic table, X, Y-axis stepper drive, Z-axis servo drive,

X-Y-Z stroke 450mm × 1500mm × 150mm, positioning accuracy of 0.04mm,

Repeat positioning accuracy ± 0.02mm, plus two electric rotary table;

◆ Can be welded to the fan fan and the axis of the cylindrical curve, two-station rotation welding;

◆ To meet the welding point, straight, round, square and other plane graphics and space curve of the welding.

|

|

|

|

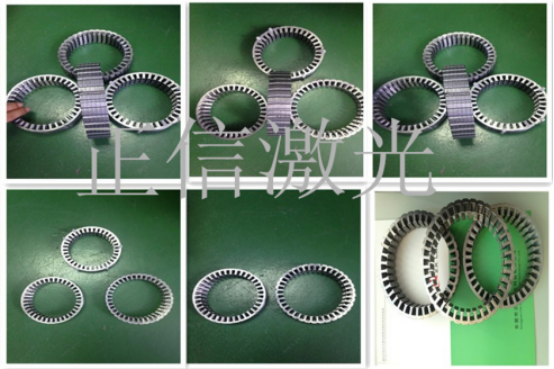

Motor core welding table HWLJJ01

◆Industrial PC control,

Dimensions: (L * W * H): 700 × 800 × 1400 (mm);

◆The overall use of two-dimensional Taiwan design, laser head movement,

X, Y axis for the step drive, stroke for the 400mm × 150mm,

Positioning repeat accuracy of ± 0.03mm,

Laser head up and down 120mm manual lift focus,

About 45 ° manually adjustable;

◆One end of the work surface with pneumatic clamping fixture,

Easy to clamp, improve production efficiency.

|

|